Rail

Ascon Africa experiences cover the study, planning, design, project management and construction of railway facilities in Zimbabwe, Zambia, Botswana, Malawi and South Africa, ranging from: Mainline construction and alignment/grade improvement to service sidings, marshalling yards for new or existing industrial areas to

• Main Line Projects (including new, [route location] alignment/grading improvements etc)

• Service sidings and marshalling yards to new and existing industrial areas

• Private sidings from small to large and very specialised.

Experience and work undertaken covers the following:

• Topographical and environmental surveys

• Soil surveys and studies (including foundations)

• Surveys of construction materials

• Feasibility studies (to assess engineering and economic viability including establishment of alignments)

• Detailed design

• Liasion with Railway Authorities, Government and Local authorities including all necessary documentation.

• Contract documents

• Specification and tendering procedures

• Contract administration

• Supervision and construction

• Project management.

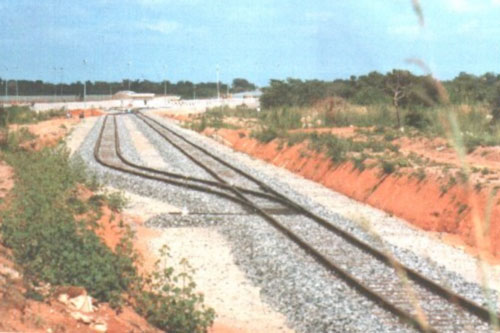

Sino Zimbabwe Cement Project, Indiva Rail Facilities

This is Zimbabwe’s third largest cement manufacturing plant with a proposed cement output of approximately 1 000t/day.

To assist in servicing the plant (both with incoming and outgoing bulk materials), railway facilities have been designed and constructed. These facilities have a total combined length of approximately 4km and a construction value of US$4.0m.

The rail facilities consist of:-

• An approach line

• An Exchange Yard of three tracks (with a capacity of 70 wagons)

• A secondary approach line (Exchange Yard to Factory)

• A factory track layout of three tracks and water feed cross-overs with a wagon capacity of approximately 50 wagons

The rail facilities are serviced both by the National Railways of Zimbabwe and Sino’s own16 ton shunt locomotive.

Construction of the rail facilities has taken approximately 15 months to complete.

Noczim Fuel Terminal at Ventersburg (Harare East), Zimbabwe

The study, preparation and cost of two alternative access routes (approx. 5Km) to serve the above Fuel terminal for the Harare to Mutare oil pipeline.

Resulting from the recommended route, the carrying out of detailed discussions with existing land owners including liasion with Railway, Government, Environmental, Local authorities and various large industrial manufacturers adjacent to or in close proximity of this fuel terminal and its associated access line.

Included in the rail facilities are loading tracks of approximately 750m in length (set in concrete for spillage/pollution control) as well as tank car reception tracks and associated run around facilities for the N.R.Z. shunts.

The rail facilities (including the approach route) were planned to accommodate the future overall industrial development of the Ventersburg area.

Manica Freight – Container Park Harare, Zimbabwe